Pump Line Information

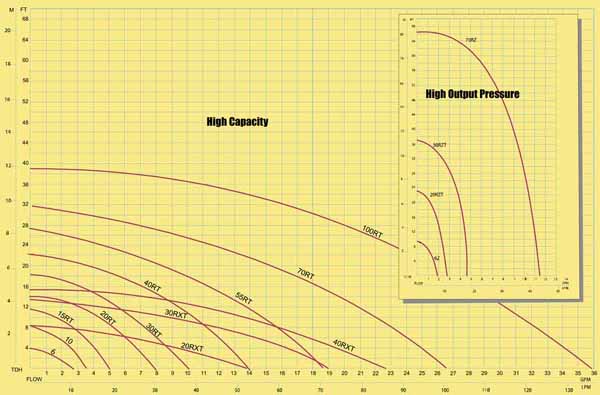

Ampco Centifugal Pumps

What is a Centrifugal Pump?

A centrifugal pump is probably the most common pump in use. A rotating impeller draws fluid along the axis of rotation, imparts kinetic energy by "flinging" material laterally. The pump cavity channels the flow in one direction, towards your outlet piping.

Why Centrifugal Pumps?

- Mechanical Simplicity. Only one moving part.

- Most economical choice in terms of price-to-flow

- Tolerance to solids

Why Ampco AC Series Centrifugal Pumps?

- Dimensionally and hydraulically interchangeable with TriClover Centrifugal Pumps. Ampco pumps also have the same materials of construction.

- Available with mechanical seals, single mechanical seal with drip and double mechanical seal with flush.

- Ampco pumps are often a more economical choice than TriClover for what is for all intents and purposes the same pump.

- Sanitary Tri-Clamp connections are standard, BSP or NPT are also available.

- Ampco pumps are a SIP (Stip-in-place) cleanable.

Typical Applications

- Transfer of virtually any material that requires a sanitary pump.

- Transfer of sanitary fluids with moderate solids content.

- Feed of Cleaning solution to CIP (Clean-in-place) pumps.

- Flow rates up to 1040 GPM or 300 ft Head (130 psi)

- Call us at 888-289-8787 to discuss your application or BPH's Trial Program!

Jabsco Rotary Lobe Pumps

What is a Rotary Lobe Pump?

A rotary lobe pump features a rotating set of interlocking rotors that rotate in synch with one another. Typically a gear box behind the pump cavity keeps the rotors in appropriate phase with one another.

Why Rotary Lobe Pumps?

Rotary lobe pumps are used quite often in food and sanitary applications because of their cleanability and flow at pressure capability. If you require a cleanable pump, a rotary lobe is often your best choice. Rotary lobe pumps are often an attractive alternative to stainless steel gear pumps.

Many liquids are "heavier" or "thicker" than water, which changes the performance and motor requirements for a given pump. If your application calls for such a liquid, we strongly recommend that you talk to us prior to ordering. We're at 888-289-8787.

Why Jabsco Rotary Lobe Pumps?

Front Loaded Seals

- No timing or shimming when changing seals. This is a big time and hassle savings especially compared to other manufacturers.

- True Clean-in-place. Simply the velocity of your cleaning fluid is adequate to clean the seals.

Scimitar Rotor

- Non-contacting design means a lower maintenance cost.

- Long slip path makes for efficient operation, especially with higher viscosity products. This leads to increased product integrity.

Cleanability

- Jabsco Pumps are true Clean-in-place pumps.

- Most models meet 3A, FDA, and USDA standards.

- Hyline and Ultima models meet EHEDG—pump cleans as well as a straight piece of pipe.

Typical Applications

- Flow rates up to 554 GPM and 215 psi.

- Dairy and cheese

- Confectionary and chocolate

- Meat

- Call us at 888-289-8787 to discuss your application or BPH's Trial Program!

Flux Sanitary Drum Pumps

What is a Sanitary Drum Pump?

A drum pump consists of a pump tube, which is typically inserted into a drum or tote of your material. The pump elements are located at the bottom of the tube. A separate and modular motor is mounted atop the tube to drive the pump's rotating element.

A Sanitary Drum pump works along the same basic principle, except the design meets FDA and 3A standards. A smooth surface finish and design that has no "nooks and crannie" keeps the risk of bacterial growth low.

Why Sanitary Drum Pumps?

- Safety. Eliminate exposure from hand pumping.

- Product Integrity. A cleanable pump with appropriate cleaning procedures makes your product safer, and reduces quality control risks.

- Attractive Price Point

- Low Cost of Ownership from few moving parts

- Pulsation Free

- Inherent flooded suction

- Stainless Steel and Teflon materials minimizes product contamination

- Available in pump tube lengths that match your needs

Why Flux Sanitary Drum Pumps?

- Only 3A Approved drum pump on the market

- Only Strip-in-place drum pump on the market

Typical Applications

- Flow rates up to 50 GPM and 120 psi.

- Transfer of food or pharmaceutical grade products

- Transfer of products requiring a cleanable 3A pump

- Fluids include tomato paste, honey, juice concentrate, gels, syrups, pharmaceuticals, wines, sauces, perfumes

- Call us at 888-289-8787 to discuss your application or BPH's Trial Program!

Jabsco Flexible Impeller Pumps

What is a Flexible Impeller Pump?

A multi-vaned flexible rubber impeller rotates within an asymmetric pump cavity. The only wear parts are the impeller itself and a mechanical seal.

Why Flexible Impeller Pumps?

- Excellent Self-Priming pump. We guarantee a 5' suction lift.

- Excellent Choice for air-entrained products

- Reversible rotation

- Moderate solids handling capability

Why Jabsco Flexible Impeller Pumps?

- Product Integrity and cleanliness. Selected Models of Jabsco Flexible Impeller pumps are Strip-in-place cleanable. An appropriate cleaning procedure minimizes the risk of quality control issues.

- Impeller replacement cost is quite reasonable, especially compared to a floating rotor design

Typical Applications

- Any fluid up to 20,000 CP, or 60 PSI, or 100 GPM

- Transfer of food grade materials such as dairy products, cosmetics, foods, sauces, wines, fruit juices, etc.

- Call us at 888-289-8787 to discuss your application or BPH's Trial Program!

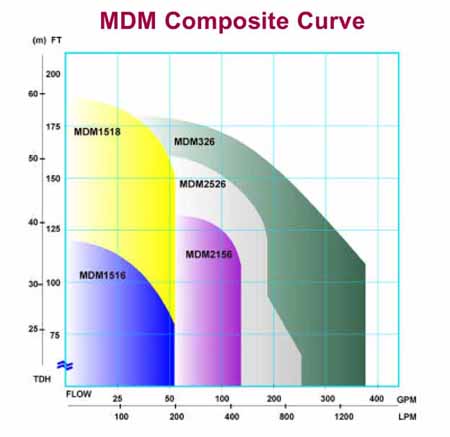

Iwaki MDM Teflon Lined ANSI Mag Drive Centrifugal Pumps

What is a Centrifugal Pump?

A centrifugal pump is probably the most common pump in use. A rotating impeller draws fluid along the axis of rotation, imparts kinetic energy by "flinging" material laterally. The pump cavity channels the flow in one direction, towards your outlet piping.

Why Centrifugal Pumps?

- Mechanical Simplicity. Only one moving part.

- Most economical choice in terms of price-to-flow.

- Tolerance to solids.

Why Magnetically Driven?

- No mechanical seal eliminates the most common leakage point.

- Best choice when dealing with chemicals that are aggressive or can produce harmful vapors.

- Good choice for fluid applications under partial vacuum.

MDM Series offers features that ANSI-Mag, Innomag and ITT Goulds can't:

- Run Dry capability from strong centering magnets that ensure your pump impeller won't rub against the back of the impeller case.

- Cavitation protection from cool-running rear contact surfaces.

- Temperatures to 150° C (302° F)

- Up to 20% entrained air handling capability

- Up to 10%, 50-micron solids handling capability

- Separate impeller, front casing and rear casing liners. Unlike the competition, there is no need to purchase the impeller/driven magnet; front casing/liner; or rear casing/support shell as assemblies. All these items are available as individual components, which reduces spare parts costs to a fraction of what competitors demand!

-

Hollow Spindle is dual supported for better heat dissipation and greater strength.

- Back Pullout Design allows inspection of the pump without having to disconnect it from process piping.

- High Purity from ETFE or PFA encapsulated magnets and impeller, and removable ETFE casing. If parts per billion or parts per trillion ionic purity determine the success of your process, look no further!

- Flows up to 350 GPM

- Heads over 350 ft

Cat Ceramic Plunger Pumps

What is a Piston Pump?

A piston pump is like a car engine-but backwards. External power moves a reciprocating piston. The piston moves the process fluid. Valves keep the flow moving in the correct direction.

Why Piston Pumps?

- Piston pumps offer very high pressure capabilities, as well has high reproducibility.

- Multiple pistons, when staged out of phase, can offer very low pulsation.

Why Cat Piston Pumps?

- ISO9001 manufacturing facility ensures reproducible quality, every time.

- Concentric centerless ground high density ceramic plungers use a graphite impregnated surface maximizes your seal life.

- Long lived seals, from proprietary seal material.

- Excellent inventory and short lead times.

Typical Applications

- Flow rates up 450 GPM and up to 10,000 psi.

- Machine tool flushing

- Car wash systems

- High pressure washing

- Reverse Osmosis (RO) systems

- Chemical injection

- Call us at 888-289-8787 to discuss your application or BPH's Trial Program!

Hypro PowerLine Plus Duplex Plunger Pumps

What is a Piston Pump?

A piston pump is like a car engine-but backwards. External power moves a reciprocating piston. The piston moves the process fluid. Valves keep the flow moving in the correct direction.

Why Piston Pumps?

- Piston pumps offer very high pressure capabilities, as well has high reproducibility.

- Multiple pistons, when staged out of phase, can offer very low pulsation.

Why Hypro Powerline Piston Pumps?

- Patented, one piece plunger guide cartridge provides improved guiding surface for superior alignment.

- Precision machined SS valve and seats provide chemical resistance

- Long lasting drive system with heavy duty roller bearings

- Stainless stell lower plungers and ceramic upper plungers offer high pressure capability and chemical resistance

- Easy-to-replace packing can be serviced in just a few moments

Typical Applications

- Flow rates up 4 GPM and up to 3,000 psi.

- Machine tool flushing

- Car wash systems

- High pressure washing

- Reverse Osmosis (RO) systems

- Chemical injection

- Call us at 888-289-8787 to discuss your application or BPH's Trial Program!

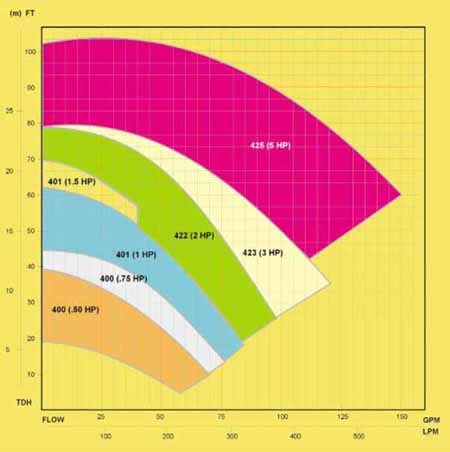

Iwaki-Walchem Mag Drive Centrifugal Pumps

What is a Centrifugal Pump?

A centrifugal pump is probably the most common pump in use. A rotating impeller draws fluid along the axis of rotation, imparts kinetic energy by "flinging" material laterally. The pump cavity channels the flow in one direction, towards your outlet piping.

Why Centrifugal Pumps?

- Mechanical Simplicity. Only one moving part.

- Most economical choice in terms of price-to-flow

- Tolerance to solids

Why Iwaki-Walchem Mag Drive Centrifugal Pumps?

MD Series

- Twin Bearing System handles thrust loads and extends service life.

- Hollow Rotating Element and Internal Cooling Circuit reduces bearing temperature for extended service life

- Compact and Energy Efficient Design

- Up to 35.6 GPM or 39 ft head (16.9 psi)

MDH-D Series

- Run Dry Capability from Pinpoint Thrust Bearing which balances the magnet capsule and impeller assembly to eliminate heat generation and allows the pump to be operated in a dry running mode for up to 8 hours (combined). Running any pump dry is never a good idea, but with this bearing, you significantly reduce the risk of trashing a pump.

- Better Bearing Cooling from Bearing Flush Grooves which insure there is always a clear path for the process fluid to move through the bearing system, thus bearings are adequately cooled.

- Integral Thrust Surfaces prevent contact of the magnet capsule with the rear casing under abnormal operating conditions--thus extending pump life.

- Lower Cost of Repair from a impeller that can be replaced with your original magnet assembly. Additionally, there are only five assemblies to work with!

- Increased Baseplate Survivablility from a reinforced plastic pump base.

- Up to 150 GPM or 102 ft head (44 psi).

MDH-F Series

- The MDH-F Series is similar in construction to the MDH but has a wetted parts of fluoroplastic for high purity applications.

- Up to Up to 150 GPM or 102 ft head (44 psi).

MDF-L Series

- The MDF-L Series is similar in construction to the MDH but has a flouroplastic liner inside a heavy duty iron casing for high purity applications.

- Up to 150 GPM or 135 ft head (57 psi).

SMD Self-Priming

- Run Dry Capability from Pinpoint Thrust Bearing which balances the magnet capsule and impeller assembly to eliminate heat generation and allows the pump to be operated in a dry running mode for up to 8 hours (combined). Running any pump dry is never a good idea, but with this bearing, you significantly reduce the risk of trashing a pump.

- Superior Priming from patented priming chamber. Fill the resevoir once and you get 13' self priming in three minutes for the life of the pump installation.

- Up to 75 GPM or 50 ft head (21 psi).

MDM Series

- Run Dry capability from strong centering magnets that ensure your pump impeller won't rub against the back of the impeller case.

- High Purity from ETFE or PFA encapsulated magnets and impeller, and removable ETFE casing. If parts per billion or parts per trillion ionic purity determine the success of your process, look no further!

- Hollow Spindle is dual supported for better heat dissipation and greater strength.

- Back Pullout Design lets you inspect the pump without having to disconnect it from process piping

- Priced very competitively on a given size, and we are often a more efficient running pump.

- Up to Up to 350 GPM or 185 ft head (80 psi).

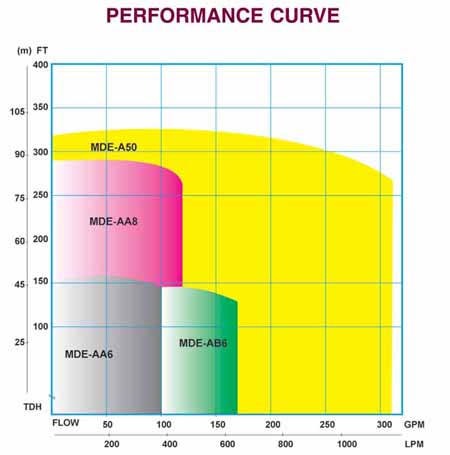

MDE Series

- Fully retrofittable into existing ANSI pump installations with no requirements for piping changes.

- Chemical resistance and wide range potential applications from available in ETFE or PFA materials.

- Low cost of ownership with field replaceable front casing liner.

- SiC bearing and thrust surface offers one common bearing material to cover a wide range of applications.

- Longer service life from flushed bearing groove.

- Up to 120 GPM or 280 ft head (121 psi).

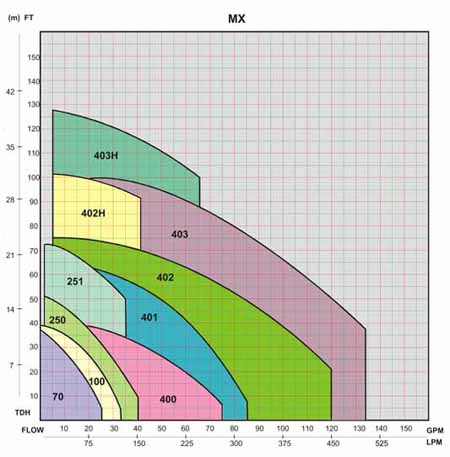

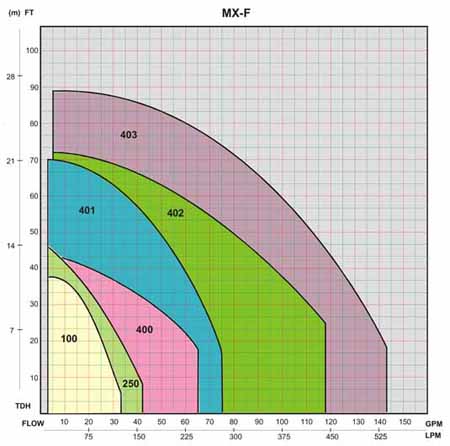

MX Series

- Better efficiency, higher pressure, lower power required, greater flow from true volute casing. A volute casing channels the process fluid.

- Run Dry capability from strong centering magnets that ensure your pump impeller won't rub against the back of the impeller case.

- Better cooling for longer life from heat dissipation holes, flush grooved bearing, and self-radiating shape. In dry run mode, air is channeled to bearing surfaces. In the (strongly preferred) flooded inlet mode, process fluid is effectively forced through bearing assembly for more effective cooling.

- Reduced risk of cavitation and longer service life from a spindle that is supported on both ends. Many competitive designs have a spindle that acts like a cantilever or "Diving board" because they are attached only in the rear of the pump casing.

- Flexibility. Each size has both a standard and a high head impeller.

- Protection from mistakes. Piping connections are male. Should a connection be overtorqued, the relatively inexpensive pipe will usually fail before the more expensive pump case.

- Lower maintenance costs. The impeller and magnet on sized MX(F)250-403(H) are separate parts. Should an impeller need to be resized, or a magnet replaced, we offer a product with lower parts costs.

- Increased relability from spline connection on MX(F)402-403(H). Spline and pin construction prevents impeller from coming apart during accidental reverse rotation.

- Up to 132 GPM or 101 ft head (43 psi).

Typical Applications

- Transfer of virtually any material, corrosive or otherwise. Iwaki-Walchem Centrifugal pumps are all plastic in their core construction, so are perfect for a a wide variety of fluids. It's not question of where you use an Iwaki-Walchem pump for, it's a question of where you don't use them.

- Call us at 888-289-8787 to discuss your application or BPH's Trial Program!

Jabsco Flexible Impeller Pumps

What is a Flexible Impeller Pump?

A multi-vaned flexible rubber impeller rotates within an asymmetric pump cavity. The only wear parts are the impeller itself and a mechanical seal.

Why Flexible Impeller Pumps?

- Excellent Self-Priming pump. 15' dry suction lift on most fluids.

- Excellent Choice for air-entrained products

- Excellent Choice for shear sensitive products

- Available in a sanitary design

- Reversible rotation

- Moderate solids handling capability

Why Jabsco Flexible Impeller Pumps?

- Product integrity and cleanliness. Selected models of Jabsco Flexible Impeller pumps are Strip-in-place cleanable. An appropriate cleaning procedure minimizes the risk of quality control issues.

- Impeller replacement cost is quite reasonable, especially compared to a floating rotor design

Typical Applications

- Any fluid up to 20,000 CP, or 60 PSI, or 100 GPM

- Transfer of food grade materials such as dairy products, cosmetics, foods, sauces, wines, fruit juices, etc.

- Call us at 888-289-8787 to discuss your application or BPH's Trial Program!

Lutz Drum Pumps

What is a Drum Pump?

A drum pump consists of a pump tube, which is typically inserted into a drum or tote of your material. The pump elements are located at the bottom of the tube. A separate and modular motor is mounted atop the tube to drive the pump's rotating element.

Why Drum Pumps?

- Safety. Eliminate exposure from hand pumping.

- Low cost of ownership from few moving parts

- Pulsation free

- Inherent flooded suction

- Seal-less and quiet

- Available in a variety of materials including Polypropylene, PVDF, Stainless steel, Aluminum, Hastelloy C.

- Available in pump tube lengths that match your needs.

Why Lutz Drum Pumps?

Lutz's Hand Wheel

- Motor quickly connects to pump tube, acts as handle. Enables a dedicated pump tube for a given chemical to minimize cross contamination. Easily switch motors between tubes. Lutz's hand wheel was invented in 1962 and continually improved upon.

Flange/Bearing Housing

- Assembly is in anodized alloy, electroless nickel plated for chemical resistance.

- Has cooling fins for heat dissipation

- Weep hole/fume exit port keeps vapor phase material from corroding your pump and motor

Other Benefits

- Connection options include 1/2", 3/4", 1" 1 ¼" hose barb, or hard piping

- Drive shaft is constructed of 316SS or Hastelloy C

- Guide bushing is of chemically resistant and self-lubricating Tefzel

- Pump foot is in chemically resistant and sturdy PVDF. Design easily snaps on and has no wearing threads

Typical Applications

- Chemical Transfer up to 56 GPM or 30 PSI.

- Dispensing of chemicals from drums or totes.

- Emptying drums or totes

- Call us at 888-289-8787 to discuss your application or BPH's Trial Program!

Oberdorfer ChemSteel Gear Pumps

What is a Gear Pump?

A "Spur Gear" or "External Gear" pump has two interconnected gears that rotate within a figure-eight shaped cavity. Fluid is trapped between the gear teeth and the cavity wall, and is transported along the inner walls of the pump cavity.

Why Gear Pumps?

- Gear pumps are an ideal choice for viscous products.

- Gear pumps lose performance gradually, and generally won't fail catastrophically.

- Since they are positive displacement, the flow rate degradation is directly proportional to TDH.

- Gear pumps don't shear fluid as much as other pump technologies.

- Gear pumps are essentially pulseless positive displacement pumps. This makes them ideal for pulse sensitive applications or where you need to install a flowmeter near the pump output.

Why Oberdorfer Centrifugal Pumps?

- Quiet operation, longer gear life, and less product shear from helical gears

- Longer bearing life from slotted bearing surfaces which balances axial load

- Reduced NPSHr, and greater installation flexibility from larger port size

- Better sealing and no cold flow with TFE Encapsulated o-rings. This reduces the need for re-torquing> at start-up, longer seal life, and reduces head related shrinkage of the pump body

- Reduced likelihood parts will get damaged during pump repair and re-assembly because Bearing and wear plate function are combined.

- Available with the "big three" of sealing concepts. Magnetic Coupling, Mechanical Seals, or packing Mechanically Sealed ChemSteel Pumps

- Flow path on all pumps can adjust for pressure in low vapor pressure fluid applications

- Pratt Key in magnetically coupled design is much easier to work with than Woodruff keys found in competitor's products

Magnetically coupled ChemSteel Gear Pumps

- Reduced eddy current heating effects in magnetic coupled pumps from exclusive cooling loop

- Flully encapsulated magnet hub protects magnet from chemical attack in magnetic coupled pumps.

Typical Applications

- Flow rates up 30GPM and 150 psi differential pressure and viscosities up to 20,000 cp

- Metering. Though often not thought of as a metering pump, Oberdorfer gear pumps are more than accurate enough for most metering applications

- Polymers, acids, caustics, oxidants and reductants

- Call us at 888-289-8787 to discuss your application or BPH's Trial Program!

Price Centrifugal Pumps

What is a Centrifugal Pump?

A centrifugal pump is probably the most common pump in use. A rotating impeller draws fluid along the axis of rotation, imparts kinetic energy by "flinging" material laterally. The pump cavity channels the flow in one direction, towards your outlet piping.

Why Centrifugal Pumps?

- Mechanical simplicity. Only one moving part.

- Most economical choice in terms of price-to-flow

- Tolerance to solids

Why Price Centrifugal Pumps?

- Most versatile centrifugal pump

- Quick response to unusual requirements or especially rapid delivery needs

- Wide range of seal options

- Availability of magnetically driven pumps

Typical Applications

- Transfer of virtually any material, corrosive or otherwise. It's not a question of what you use a Price pump for, it's what don't you use them for.

- Call us at 888-289-8787 to discuss your application or BPH's Trial Program!

Webster Vertical Immersible Pumps

What is a vertical pump?

A vertical pump is a centrifugal pump whose motor is mounted in an "up and down" orientation. This means the fluid and motor are separated by gravity and a fume barrier, not a more elaborate mechanical seal or magnetic coupling. The key advantage is cost.

Why vertical pumps?

- Vertical pumps are often an economical choice for a given application

- Vertical pumps are ideal for circulation baths, coolant, or filtration.

Why Webster Vertical Immersion Pumps?

- Optimum chemical resistance with choice of CPVC Corzan®, fiberglass reinforced Polypropylene, or PVDF Solef®

- No metal in contact with fluid being pumped

- Seal-less design eliminates leaking, costly seal replacement and down time

- Viton® "O" ring end cover seal allows mounting in liquid, or with inlet extension

- Non-overloading, continuous duty totally enclosed motors

- Teflon® fume barrier protects motor end bell and bearings from corrosion caused by vapor or fumes

Typical Applications

- Flow rates up to 130 GPM and up to 115 feet of head

- Perfect for aeration, agitation, filtration, recirculation, spraying, transfer

- Call us at 888-289-8787 to discuss your application or BPH's Trial Program!

Yamada Air Operated Double Diaphragm Pumps

What is Air Operated Diaphragm Pump?

An air operated diaphragm pump uses compressed air to drive two flexible, elastomeric diaphragms. Four check valves are used to maintain discharge pressure and control flow direction.

Why Air Operated Diaphragm Pumps?

- Arguably the most "bullet proof" pump technology. Very tolerant of solids, or viscous materials. Excelent for biodiesel pump applications.

- In the event of a dead head condition, the air operated diaphragm pump simply stops running, instead of breaking shafts and valves.

- Air operated diaphragm pumps are intrinsically safe when properly grounded.

Why Yamada Air Operated Diaphragm Pumps?

- The finest air valve made, period. Yamada air valves are non-lubricated. They don't attract dirt, run longer, and are more reliable. The valves are also spring assisted, and use an internal geometry that reduces water build-up within the valve. BPH is so confident of the performance of this valve, we are more than willing to embark on a trial program. Call for details.

- Short stroke length with a larger diameter diaphragm actually gives you increased diaphragm life from decreased mechanical stress.

- Two independent pilot valves have a static seal instead of a dynamically sealed and coupled pilot valve found on most competitive designs. This leads to more reliable operation.

Typical Applications

- Transfer of materials up to 166 GPM or 100 PSI.

- Biodiesel Manufacture

- Powder transfer applications

- Explosion-proof environments.

- Call us at 888-289-8787 to discuss your application or BPH's Trial Program!

Velocity Filtration Filters

What Filtration Is Available?

We offer filter housings suitable for use with cartridge or bag filters. Call us if you need bases or pumps for a complete system.

Why Cartridge or Bag Filter Assemblies?

- Cartridge and bag filters are used to "scrub" fluids and remove particulates of all kinds. Typically, the pore size of the filter media dictates the particle size distribution that move past the filter media. Smaller pore sizes remove more particulate.

- Bag filters are used for lots of larger particles. Cartridge filters are typically better suited to removing smaller particulates.

Why Velocity Cartridge and Bag Filter Assemblies?

- We include a sample port/air bleed valve and pressure gauge and guard. We feel this is equipment that should be on every filter housing, so we include it as standard. This means safer operation, and quicker installation for you.

- We use a gasketed top cover that is secured by stainess steel washer/bolt assemblies. Compared to other filter housings, this is just a tougher, more resiliant way of securing your lid. The benefit? Longer life and lower total cost of ownership.

Typical Applications

- Max filtration rates from 400 GPH to 28,000 GPH.

- Removal of particlate matter prior to water treatment.

- Removal of particulate matter in plating applications.

- Call us at 888-289-8787 to discuss your application or BPH's Trial Program!